Svoboda Press s.r.o. focuses on long run web offset printing.

We print mainly magazines and advertising printed materials, e.g. catalogues or leaflets. Printed materials can be folded or continuously cut, stitched, glued or cased in a cover.

The predominant technology in the company is heat-set web offset. For printing of our products we use 5 web printmachines and the existing machinery is constantly being modernized.

Saddle stitching:

more

For saddle stitching there are three Müller Martini machines available in Svoboda Press s.r.o., where up to nine sections plus cover can be gathered, and stitched by up to four wires. A supplement can be glued in.

Perfect binding

more

For perfect binding there is a Müller Martini Trendbinder. The machine is able to bind printed materials with the spine width from 3 up to 60 mm. Into these copies can be inserted supplements up to the weight of 120 g and 10 mm strength, e.g. CD carriers.

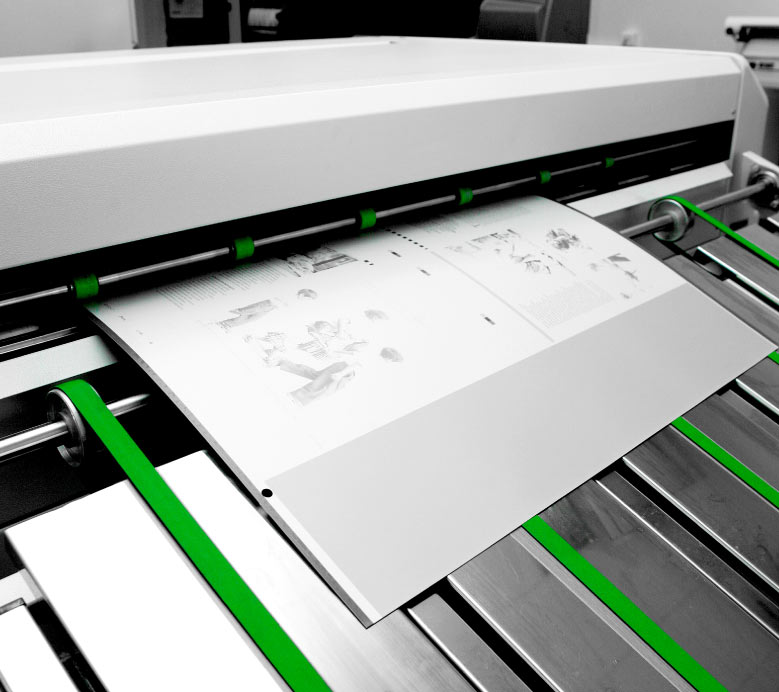

Prepress

more

Svoboda Press is equipped with the system CTP KODAK. Data is accepted in the PDF form, possibly also with proofs and dummies. The client can approve the ripped data on screen – via electronic preview “impo2go” or “pdf2go” or via the Web interface Kodak InSite.

Postpress

more

An important step after every processing! All our products as brochures, leaflets, catalogues or magazines can be wrapped into a foil, strapped, put in cartons.

Storage and logistics

more

We ensure delivery of our production to places determined by our customers, throughout the Czech Republic and other EU countries as well as outside the EU.

Complete technology

The most modern machine equipment

PRINTING MACHINES

Lithoman IV 64

2 x Lithoman IV 48

Rotoman N 16

Rotoman 50 16

Lithoman III 32

Warning: Invalid argument supplied for foreach() in /data/web/virtuals/145404/virtual/www/subdom/svoboda/wp-content/themes/severotisk/page-technologie.php on line 175

Finishing

Müller Martini Tempo

min. 125x200 mm

Number of sections: 8 + cover + gluing in

Accessories: triple cut, stitching with from 1 to 3 wires

Müller Martini 300

min. 105x115 mm

max. 325x480 mm

Number of sections: up to 9 + cover + gluing in

Accessories: triple cut

Müller Martini Prima

min. 105x115 mm

max. 325x480 mm

Number of sections: up to 9 + cover + gluing in

Accessories: triple cut, 5-knife-cut (2up), possibility of loops

Müller Martini Trendbinder

min. 100x140 mm

max. 320x480 mm

Number of sections: up to 24 + cover

Accessories: triple cut, insertion

CTP

Data for print can be sent to us both in electronic and physical form which will then be transferred into digital form. Before the very print you can perform a final approval. On request, we will make high-resolution colour proofs, so that you can make sure that the printed colours are according to your requirement.

Workflow

Kodak Prinergy (RIP PDF PrintEngine)

Exposure units

Kodak Magnus 5183 VLF

Kodak Trendsetter 5880 VLF

Kodak Trendsetter 800 Quantum

Preview plotters

Epson StylusPro 11880

Canon 9400s

Digital proof

GMG ColorProof + Epson StylusPro 4880

GMG ColorProof + Epson StylusPro 5000

Data transfer, communication and approval via the internet

Kodak InSite

FTP server SVOBODA Press s.r.o.

Control software

Oris Certified Proof

Mellow Colour PrintSpec

iQIP (Techkon plugin)

Certification

ISO 12647-2:2004

PSO IPM

OTHER EQUIPMENT

OTHER EQUIPMENT

Cutting machine (guillotine) Polar 137

OTHER EQUIPMENT

Foil wrapping machine

OTHER EQUIPMENT